Companies across sectors count on reliable stretch wrap machine repair for continuous output.

Companies across sectors count on reliable stretch wrap machine repair for continuous output.

Blog Article

Recognizing the Significance of Timely Stretch Cover Device Fixing Solutions

When it concerns extend cover machines, timely repair services can make all the difference. You know that also small mechanical or electric issues can cause unanticipated downtime, impacting your production line. Resolving these troubles promptly not just preserves efficiency but also improves the top quality of your covered products. What elements should you think about to assure your equipments remain in leading form? Allow's discover this vital facet further.

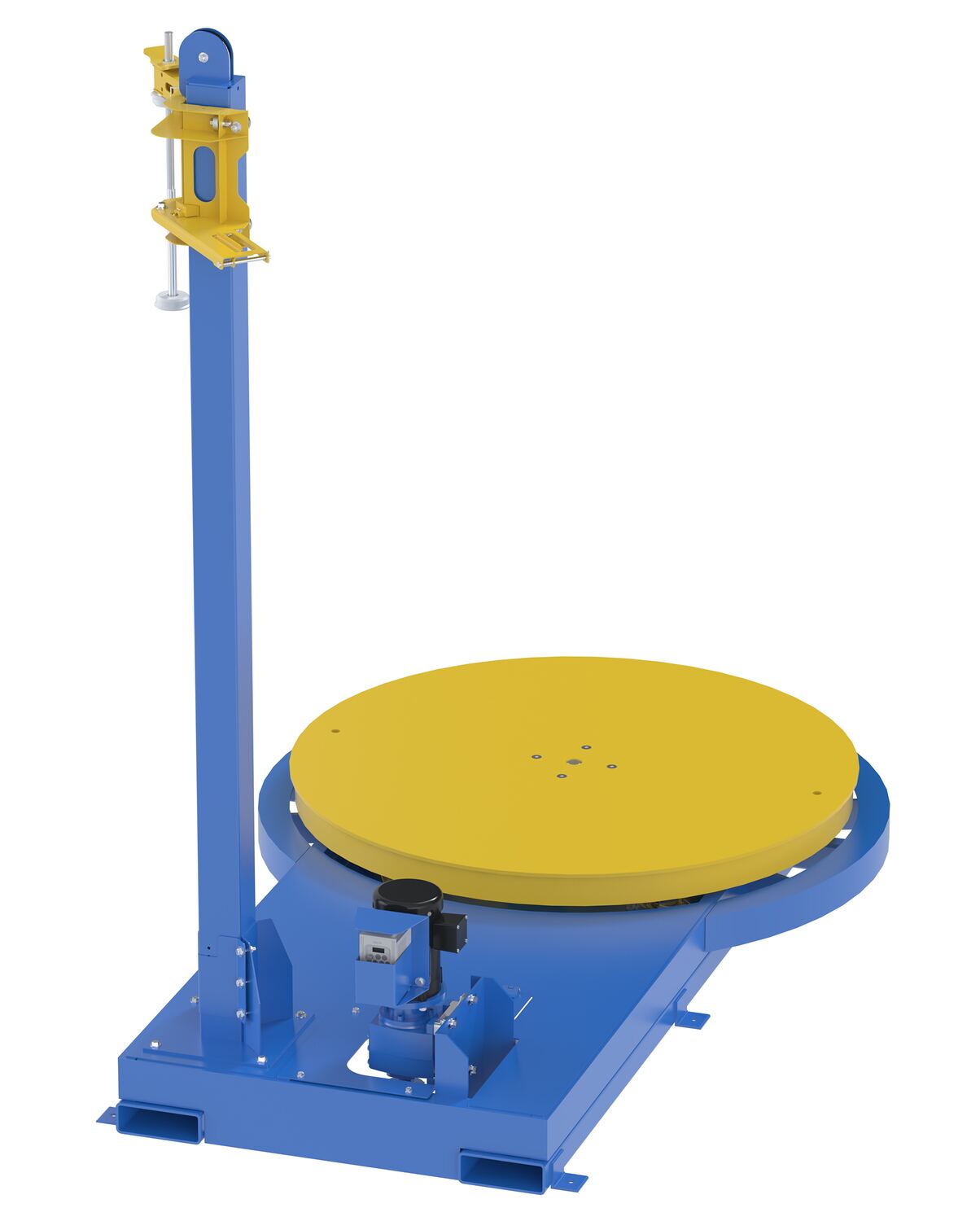

The Function of Stretch Wrap Machines in Modern Manufacturing

Stretch wrap machines play a necessary function in contemporary manufacturing by making sure that products are securely packaged for transportation and storage space. You rely upon these makers to supply stability and security, avoiding damages throughout transit. When you utilize stretch wrap, you minimize the threat of products moving or obtaining crushed, which can lead to expensive losses.

Additionally, using stretch cover devices can enhance your overall supply chain effectiveness. By enhancing the packaging process, you minimize labor costs and accelerate shipment times, making sure that your clients receive their items quickly. In today's hectic market, this benefit is important.

Typical Issues That Lead to Equipment Downtime

When your stretch cover machine experiences downtime, it can often be traced back to mechanical failings or driver mistakes. Understanding these common concerns can assist you prevent expensive disruptions. By addressing these points, you can keep your operations running smoothly.

Mechanical Failures and Break Downs

Mechanical failings and breakdowns can substantially interrupt your operations, leading to costly downtime. These concerns typically originate from worn-out components, such as gears and belts, or not enough lubrication. When components put on down or break, your stretch cover equipment may stop all of a sudden, influencing productivity. Additionally, electric failures can create malfunctions in the device's control system, developing more delays. Regular maintenance is important to catch these problems early and keep your tools running efficiently - stretch wrap machine repair. Disregarding minor issues can result in larger, more expensive fixings down the line. By focusing on timely repair work, you're not only decreasing downtime yet also prolonging the life expectancy of your machine. Remain positive, and keep your operations efficient and nonstop.

Driver Errors and Oversights

While drivers play an essential role in the smooth functioning of your stretch wrap maker, their mistakes and oversights can lead to significant downtime. Usual concerns like improper loading, incorrect settings, and failure to keep an eye on cover stress can create delays and product damage. Inevitably, spending in driver training pays off by boosting efficiency and prolonging your machine's life expectancy.

The Financial Influence of Postponed Repair Work

Postponing fixings on your stretch wrap machine can lead to significant financial effects that surge with your entire operation. When your machine breaks down, performance plummets. Each hour of downtime can cost your service not just in lost output, but additionally in labor costs as workers stand idle. You could likewise encounter enhanced material wastefulness because of incorrect wrapping, bring about higher costs for product packaging materials.

In addition, extended delays can escalate small problems right into major problems, calling for much more comprehensive fixings or perhaps complete substitute of the device. This can stress your budget plan and disrupt money flow. Hold-ups can also impact your shipment timetables, damaging client fulfillment and potentially creating you to shed business to rivals. Ultimately, timely fixings are vital to maintaining your profits and making certain smooth operations. Do not take too lightly the financial effect of neglecting those repair service requires.

Advantages of Proactive Upkeep Programs

Timely repairs can conserve you from expensive downtime, but applying a positive upkeep program takes it an action further. This not just keeps your stretch cover maker running smoothly however also expands its life expectancy.

With fewer disruptions, your labor force can concentrate on their jobs without the stress of unexpected maker failings. Keeping peak efficiency can improve the top quality of your covered products, ensuring customer fulfillment.

Recognizing Indicators That Your Machine Requirements Repair

As you run your stretch cover equipment, it is essential to stay alert for indications that show it might require fixing. Among the initial points to seek is uncommon sound. If you listen to grinding, squealing, or any type of various other odd noises, it might indicate a hidden issue. Additionally, watch for inconsistent covering. If the movie isn't stuck appropriately or you observe irregular stress, your equipment may be malfunctioning.

If your device regularly quits or like this requires changes, it is time to examine. Maintain an eye on the device's rate; if it's slower than typical, something could be wrong.

Choosing the Right Repair Work Service for Your Requirements

Exactly how do you choose the appropriate repair work solution for your stretch cover device? First, consider their experience and proficiency. Search for service technicians who focus on stretch cover machines and have a tested track record. Examine on the internet reviews and reviews to gauge client satisfaction.

Next, examine their action time. A dependable solution should offer prompt support, as maker downtime can be pricey. It's also vital to understand if they provide emergency situation fixings.

Do not neglect to ask concerning guarantees on repair services and components. A reputable service supports their work, providing you satisfaction.

Lastly, contrast prices but avoid selecting solely based on cost. Sometimes, the most affordable choice might cause below average service. By considering these elements, you'll Recommended Site discover a repair solution that fulfills your requirements and maintains your stretch wrap machine running efficiently.

Strategies for Decreasing Stretch Cover Device Downtime

Educating your operators is another essential strategy. Furnish them with the expertise to identify and deal with small problems prior to they lead to considerable failures. Encourage them to keep a log of any type of abnormalities, which aids in diagnosing issues quicker.

Furthermore, keeping a supply of important spare parts can dramatically lower downtime. When something breaks, having the right parts available implies you won't have to wait on shipments.

Finally, take into consideration purchasing real-time surveillance systems. These systems can signal you to performance changes, allowing for immediate treatment. By implementing these strategies, you'll keep your stretch cover equipment running efficiently and successfully.

Regularly Asked Inquiries

Just How Often Should Stretch Wrap Machines Be Serviced?

You need to service stretch cover makers routinely, ideally every six months. If you notice any kind of performance issues or uncommon noises, don't wait-- timetable upkeep right away to avoid costly failures and ensure peak efficiency.

What Are the Regular Expenses Related To Stretch Cover Maker Repair Works?

Typical prices for stretch wrap machine fixings vary, but you could expect to spend in between $200 to $1,500 depending on the concern. Routine upkeep can assist minimize these expenses and extend your maker's lifespan.

Can I Execute Fundamental Upkeep on My Stretch Wrap Equipment?

Yes, you can carry out standard maintenance on your stretch cover device. Regularly look for wear and tear, cleanse the components, and assurance correct lubrication. Keeping it healthy can prolong its life-span and boost efficiency.

Just how Do I Know if a Repair Service Is Credible?

To find a reputable repair work solution, check on the check this site out internet testimonials, ask for suggestions, and confirm certifications. A reputable solution will certainly give clear estimates, guarantee alternatives, and prompt communication, ensuring you feel great in their proficiency.

What Should I Perform in Situation of an Emergency Situation Equipment Breakdown?

In situation of an emergency maker failure, you need to instantly stop operations, evaluate the problem, and call your repair work solution. Maintain critical contact numbers useful, and document the issue for effective fixing when assistance shows up.

Final thought

To sum up, comprehending the value of prompt stretch cover maker repair services can substantially boost your procedures. By resolving concerns without delay, you decrease downtime and prevent costly break downs. Accepting proactive maintenance not just expands your devices's life expectancy but also boosts productivity and customer fulfillment. Keep in mind to stay attentive for signs of wear and choose a reliable repair service to keep your machines running efficiently. Spending in these services repays in the long run, guaranteeing your supply chain stays efficient and reliable.

Report this page